Presented by Amindus Consulting and Solutions

In today's world, where environmental awareness is on the rise, recycling has become a vital part of sustainable business practices. For companies involved in recycling, selecting the right machines and production lines is essential for enhancing efficiency, lowering costs, and achieving long-term success. This guide provides a detailed look at different recycling machines and production lines, helping you make an informed choice that suits your business needs.

Types of Recycling Machines

Recycling machines come in various types, each specifically designed for handling different materials and functions. Below, we examine some commonly used machines in the recycling sector.

1. Shredders

Shredders are pivotal in reducing large materials into manageable sizes. This makes them easier to process further.

Material Handling: They can process a variety of materials including plastics, metals, and organic waste. For example, industrial shredders can handle up to 5 tons of plastic waste per hour.

Automation: These machines can come with options for manual or automatic loading, boosting convenience.

Safety Features: Equipped with emergency stops and protective covers, they prioritize operator safety.

Cost: Prices typically vary from $5,000 to $100,000, influenced by size, capacity, and features.

2. Granulators

Granulators take shredded materials and cut them into small granules, preparing them for the next stage in recycling.

Precision Cutting: Granulators ensure consistent particle sizes, making them ideal for production processes.

Noise Levels: Compared to shredders, they operate much quieter, making them suitable for indoor environments.

Energy Efficiency: They generally consume less power, which is beneficial for larger operations.

Cost: Average prices range from $10,000 to $150,000 based on capacity and technology.

3. Compactors

Compactors are designed to compress materials, significantly reducing their volume for easier storage and transportation.

Types: They can be either stationary or mobile, utilizing various techniques for compression.

Material Versatility: Effective on cardboard, plastics, and metal materials, compactor efficiency can help save up to 50% on storage costs.

Space Efficiency: By compressing waste, they enable better use of storage space.

Cost: Pricing can range from $2,000 to $30,000 depending on the capabilities and model.

4. Balers

Balers compact recyclables into bales, making them easier to store and transport.

Bale Size Options: They can be customized to create bales of various sizes and weights, optimizing storage space.

Automation: Many balers offer fully automatic or semi-automatic operation, increasing ease of use.

Durability: Built to manage heavy loads, these machines are designed for longevity.

Cost: Prices typically range from $4,000 to $80,000.

5. Sorters

Sorting machines are crucial for separating materials by size, weight, and type, which is necessary for effective recycling processes.

Technologies: Many use advanced methods like optical recognition and magnetic sorting to boost efficiency.

Speed and Accuracy: With impressive processing speeds, these machines ensure high-precision sorting.

Scalability: They can be integrated easily into existing production lines.

Cost: Prices vary widely based on features, ranging from $10,000 to $250,000.

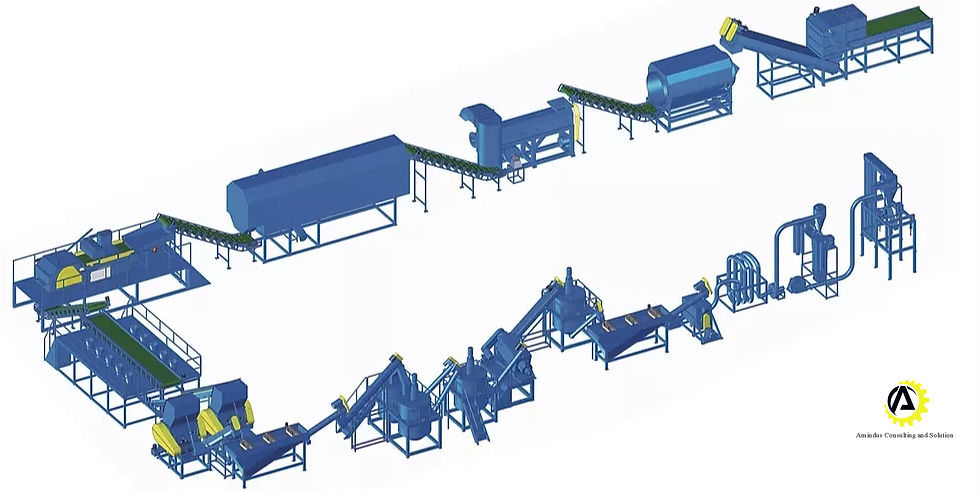

Comparing Production Lines

An efficient production line includes several machines working in harmony to optimize the recycling process. We will analyze two common types of recycling production lines: automated and semi-automated.

1. Automated Production Lines

Automated production lines rely on robotics and advanced technologies to complete recycling tasks without human help.

Efficiency: These systems can process materials faster, reducing operational downtime.

Labor Costs: They drastically lower labor costs since machines perform activities that would typically require multiple workers.

Precision: Higher accuracy in sorting and processing leads to less waste and higher recovery rates.

Cost: These systems are on the higher end of the spectrum, ranging from $100,000 to more than $500,000, depending on scale and technology.

2. Semi-Automated Production Lines

Semi-automated lines still use human operators but incorporate automation to assist in various functions.

Flexibility: They can quickly adapt to process different materials and scales of production.

Lower Initial Costs: Generally, these systems cost between $50,000 and $300,000, making them more accessible for smaller operations.

Human Oversight: Operators can monitor processes, troubleshoot issues, and ensure quality control quickly.

Key Features to Consider

When comparing recycling machines and production lines, several critical features must be considered to find the right equipment for your business.

1. Material Compatibility

Ensure the machines can handle the specific materials you plan to process. For example, if you're focused on plastics, select machines designed for that material type.

2. Scalability

Consider whether the machine can grow with your business as your recycling volumes increase. Look for equipment with modular designs that accommodate future expansions.

3. Maintenance Requirements

Assess the maintenance needs of each machine. Favor machines with easy access to support and spare parts.

4. Energy Consumption

Choose energy-efficient machines to cut down on operational costs and support sustainable practices. Some machines can reduce energy use by as much as 30%.

5. Warranty and Support

A solid warranty and responsive customer service can mitigate downtime and keep your operations running smoothly.

Cost-Benefit Analysis

Budgeting while investing in recycling machines is crucial for your success. Below, we will examine initial costs and long-term savings associated with recycling machines.

Initial Costs

Initial costs include the purchase price of equipment and potential installation expenses. It's vital to weigh these costs against your projected material processing volume.

Long-term Savings

Operational Efficiency: Investing in machines that enhance efficiency can lead to savings on labor and time. Some businesses see a return on investment within two years.

Reduced Waste: Improved sorting capabilities can minimize waste, leading to lower disposal costs.

Higher Material Recovery: Efficient machines increase the overall recovery rate of recyclable materials, which boosts profitability. For instance, some operations report enhanced recovery rates of up to 20%.

Recommended Recycling Machines and Production Lines

To assist in your decision-making, we provide a brief compilation of recommended models available in the market today.

Shredders

Intimus 14 Series: Ideal for high-volume industrial settings.

Vecoplan VAZ: Known for heavy-duty construction and consistent output.

Granulators

Cumberland Granulator: Available in various models suited for different material types.

Serpeck MRG Series: Perfect for automated production focusing on plastics.

Compactors

Bezner Efficient Compactors: Customized for particular recycling tasks.

Rem Waste Compaction Solutions: Versatile for multiple material types.

Balers

Harris Baler: Durable and adaptable for various applications.

American Baler Company: Recognized for reliable performance.

Sorters

Zero Waste Solutions: Uses AI technology for accurate sorting.

Bollegraaf Recycling Solutions: Focuses on high throughput and durability.

Making the Right Choice for Your Business

Choosing the right recycling machine and production line can significantly influence your business's bottom line. By understanding the types of machines available, their features, costs, and performance metrics, you will be better prepared to select equipment that aligns with your operational goals.

As every facility is unique, this guide is designed to provide you with a solid framework. Remember to prioritize material compatibility, scalability, and long-term savings when evaluating options.

With the right machinery, you can enhance efficiency, reduce waste, and contribute positively to sustainability. Take the time to evaluate your choices carefully, and you can transform your recycling operations for the better.

Comments